George Lister Engineering can turn your ideas into reality

Over the years we have been approached by various companies in all types of industries at the design stage with an idea which we can turn into reality. We can offer a full design facility taking your idea into manufacture.

Our company portfolio includes state of the art machines for the Pharmaceutical sector, complying with the rigorous demands of the food packaging industry and the equally stringent requirements of the Scientific equipment suppliers, Semiconductors specialists and Electron beam microscope manufacturers.

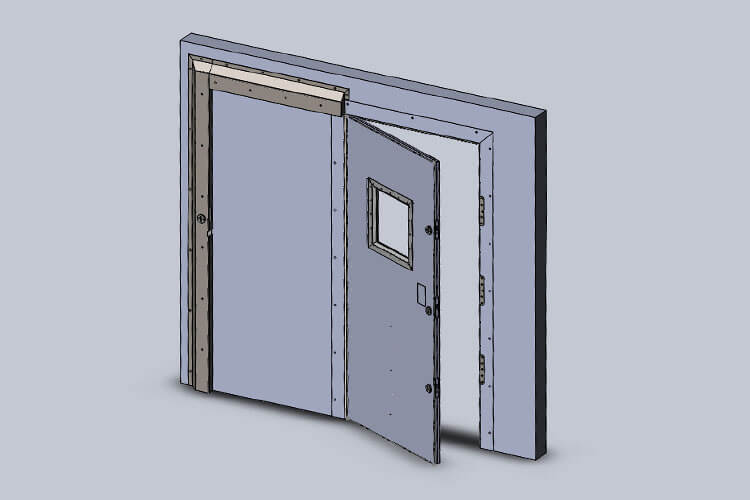

Specialist Products

We manufacture to customers specific needs an array of products to suit the medical industry.

This includes:

- Steel Seclusion Room Doors

- Anti-pass back Window guards

- Anti-ligature fixtures and fittings

- Window rebate screens

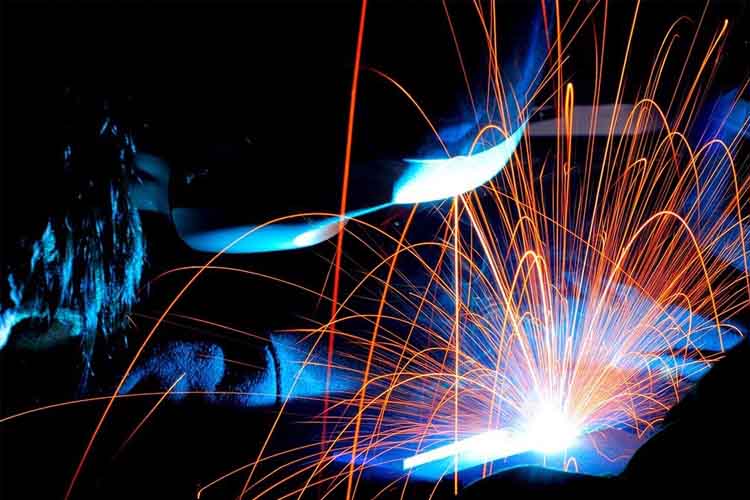

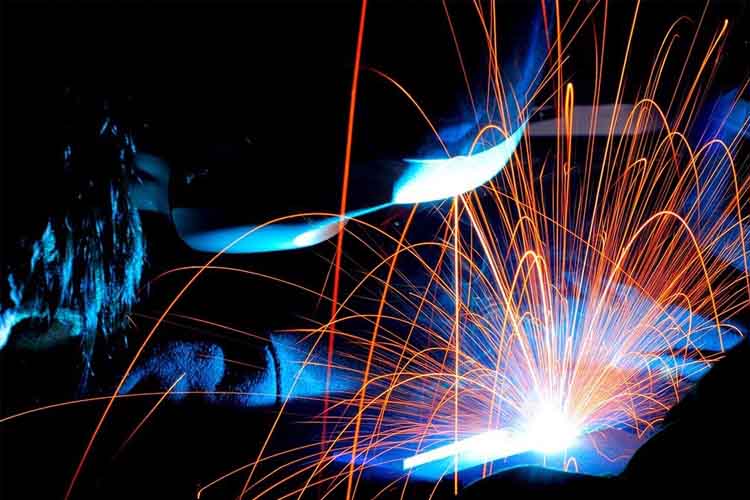

Welding & Fabrication

With over 100 years of manufacturing all industry sectors we have built our reputation on quality of service and experience in all aspects of engineering, within our facility we offer a full welding and fabrication service.

Our welding department is proficient in both Mig & Tig techniques and covers a wide range of materials including Stainless Steel, Mild Steel and Aluminium Alloys.

For further information please download our full capacity list.

Welding & Fabrication

With over 100 years of manufacturing all industry sectors we have built our reputation on quality of service and experience in all aspects of engineering, within our facility we offer a full welding and fabrication service.

Our welding department is proficient in both Mig & Tig techniques and covers a wide range of materials including Stainless Steel, Mild Steel and Aluminium Alloys.

For further information please download our full capacity list.

Architectural Curtain Walling

Within our facility we offer the manufacture of Architectural Curtain Walling and associated products, we are familiar with all the leading manufacturers systems including Kawneer, Schuco, AluK and Comar.

We work together with Architectural design companies to enable us to produce varying designs for both bespoke and commercial projects.

At George Lister Engineering we also manufacture Schuco Jansen Steel products to meet our customers design specification.

To accompany the above we also manufacture Roof Light Products for both commercial and domestic applications.

CNC SHEET METAL

Within our Sheet Metal department we have a CNC controlled Amada 28 station turret punch press that is directly programmed by the production office’s G-coder offline programming system, ensuring accurate and highly efficient manufacturing throughout all stages of the process.

To complement our punching facility we have two Amada CNC controlled HFB brake press machines with a maximum capacity of up to 4 metres.

For further information please download our full capacity list.

CNC SHEET METAL

Within our Sheet Metal department we have a CNC controlled Amada 28 station turret punch press that is directly programmed by the production office’s G-coder offline programming system, ensuring accurate and highly efficient manufacturing throughout all stages of the process.

To complement our punching facility we have two Amada CNC controlled HFB brake press machines with a maximum capacity of up to 4 metres.

For further information please download our full capacity list.

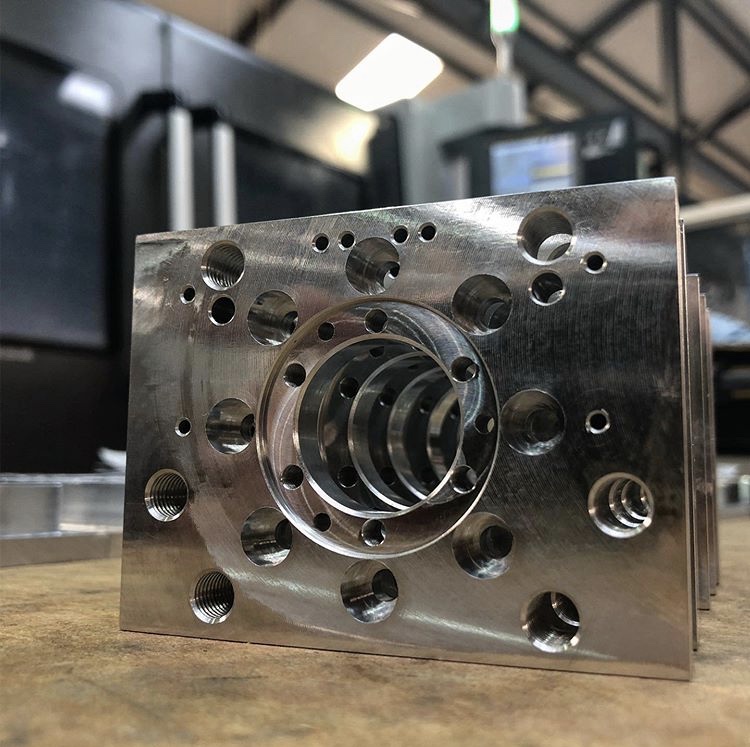

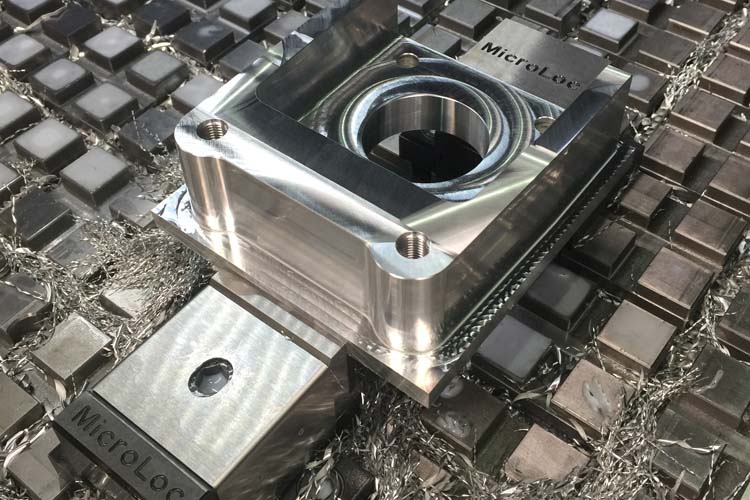

CNC TURNING

Within our turning facility we have the latest in multi axis CNC turning capabilities, with driven tooling to allow milling and turning of complex components in one operation.

All of our lathes are equipped with magazine bar feeders, for fully automated production of anything from small to large batch work up to 65mm in diameter.

We can also machine parts of up to 310mm in diameter, from a wide range of different materials.

For further information please download our full capacity list.

CNC MILLING

Within our milling facility we have the latest technology in 4 axis milling, fully equipped with high speed spindles, multi functional beds and touch probe systems for greater accuracy and efficiency.

We have five milling machines, offering capacity of up to 1700mm x 800mm x 800mm.

All of our milling machines are programmed offline using Mastercam 19, this means we can accept any customer file and work from it directly.

We are proficient in machining all materials and any batch size, from prototype 1 offs to large batch.

We also have an Elumatic SBZ130 profile cutting machine capable of machining extruded lengths up to 7.2 metres.

For further information please download our full capacity list.

CNC MILLING

Currently we have five CNC Vertical milling machines with a 4th axis capabilities ranging up in size to a maximum machining capacity of 1700 x 800 x 800mm, these are backed up with a range of Manual milling machines. We also have a fully automatic CNC profile machine centre with an X axis travelling capacity of 7.2 metres.

All machines are linked to our offline programming facilities; 2017 Solidworks + Mastercam and will accept models from most CAD drawing applications which include Dxf, Dwg, Iges & Step files.

We are proficient in machining all materials including Aluminium, Stainless Steel, Mild Steel, Brass, Copper & Plastics.

For further information please download our full capacity list.

CAD DESIGN

At George Lister Engineering we offer the latest in 3D CAD design.

Working with the most up to date Solidworks package we can take a 2D drawing in a number of formats and create a 3D image that can be rotated and viewed at any angle.

We accept most electronic files which can be easily used to aid in the manufacturing process.

THE LISTER KNOBBLY CONTINUATION

To celebrate Lister’s 60th Anniversary in motorsport 10 continuation were released for production, once again the cars from Cambridge were back! Our remit was to build exact tool room copies of this iconic car so our experienced engineers together with former employees & mechanics who worked on the cars in period set to work. The cars are completely hand built using the same drawings jigs and fixtures that Brian Lister and the team would have used back in the 1950’s.

For more information on this car and other models please visit www.listercars.com

THE LISTER KNOBBLY CONTINUATION

To celebrate Lister’s 60th Anniversary in motorsport 10 continuation were released for production, once again the cars from Cambridge were back! Our remit was to build exact tool room copies of this iconic car so our experienced engineers together with former employees & mechanics who worked on the cars in period set to work. The cars are completely hand built using the same drawings jigs and fixtures that Brian Lister and the team would have used back in the 1950’s.

For more information on this car and other models please visit www.listercars.com

You can verify the validity of our ISO certificate by entering our certificate

number 230335 via this link: www.british-assessment.co.uk/